Coliy Group

Coliy Group

|

Introduction

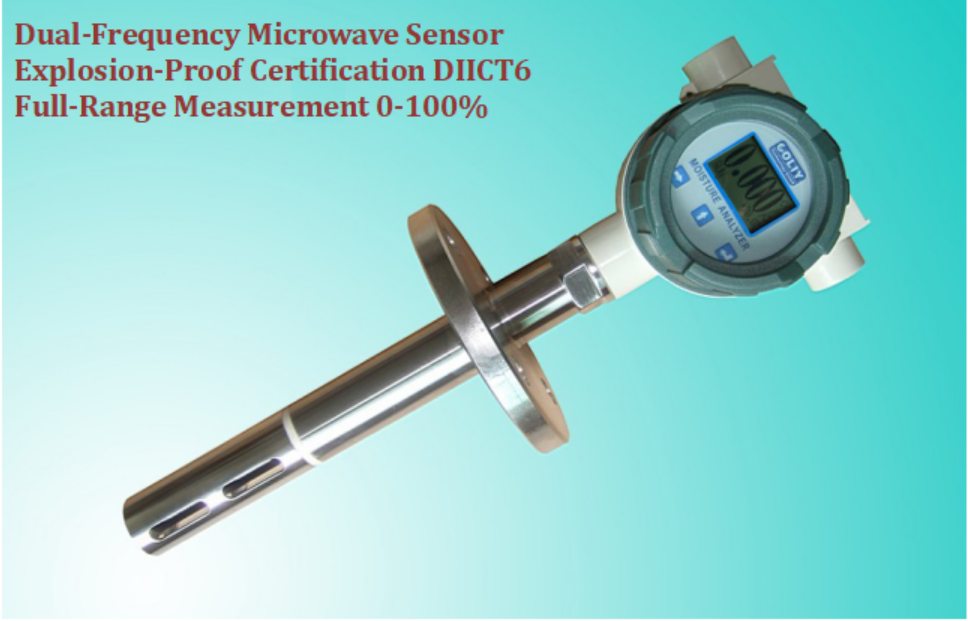

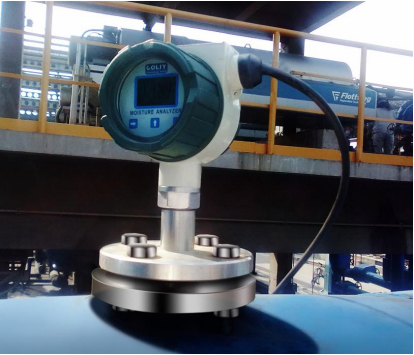

The newly upgraded W300 Online Liquid Moisture Analyzer from COLIY incorporates the company's patented dual-antenna microwave sensor, enabling precise moisture detection across a full 0–100% range—even in slightly acidic, alkaline, or other high-conductivity environments. The device features expensive perfluoroelastomer sealing rings, offering exceptional corrosion resistance and anti-aging properties to ensure long-term reliability.

The W300 is an intelligent, high-precision industrial moisture analyzer designed for liquids. Its dual-frequency microwave technology delivers superior accuracy compared to single-frequency sensors. Constructed entirely from stainless steel, the W300 is rugged, durable, and withstands pressures up to 4MPa and temperatures up to 120°C. Users can select any moisture range within 0–100%, supported by high-precision temperature compensation and a 3D calibration method with 8 preset calibration tables for diverse media.

Ideal for industrial applications, the W300 is widely used to measure moisture in oils, chemical liquids, and food/beverage products. It is insensitive to liquid color and can even measure weakly conductive media. Unlike surface-level techniques (e.g., infrared), its microwave-based depth detection penetrates the medium for more accurate results.

The W300 is CE-certified and explosion-proof certified.

Features

Built-in temperature measurement and compensation for high-precision results.

Real-time measurement with ultra-fast response (<1 second).

Stainless steel probe with PTFE fittings, ensuring corrosion and rust resistance.

No moving parts, minimizing maintenance and maximizing lifespan.

Explosion-proof (Ex ia d IICT6 Ga/Gb) and IP68-rated, suitable for harsh environments.

Dual-frequency microwave technology, unaffected by fluid state or industrial conditions.

Premium perfluoroelastomer sealing rings for extreme corrosion resistance and anti-aging performance.

Main Applications

Oil-water separation and measurement, process control for various raw/auxiliary material components.

Crude oil exploration, extraction, refining, storage, and transportation metering.

Chemical raw materials, special lubricants for aviation/aerospace/vessels, and fuels.

Fruit juices, syrups, beverages, malt extracts, alcoholic drinks, and brewing ingredients.

Additives, oil products, and material exchange/settlement during transportation.

Industries: Petrochemicals, chemicals, textiles, food & beverage, pharmaceuticals, paper, and environmental protection.

Prominent feature

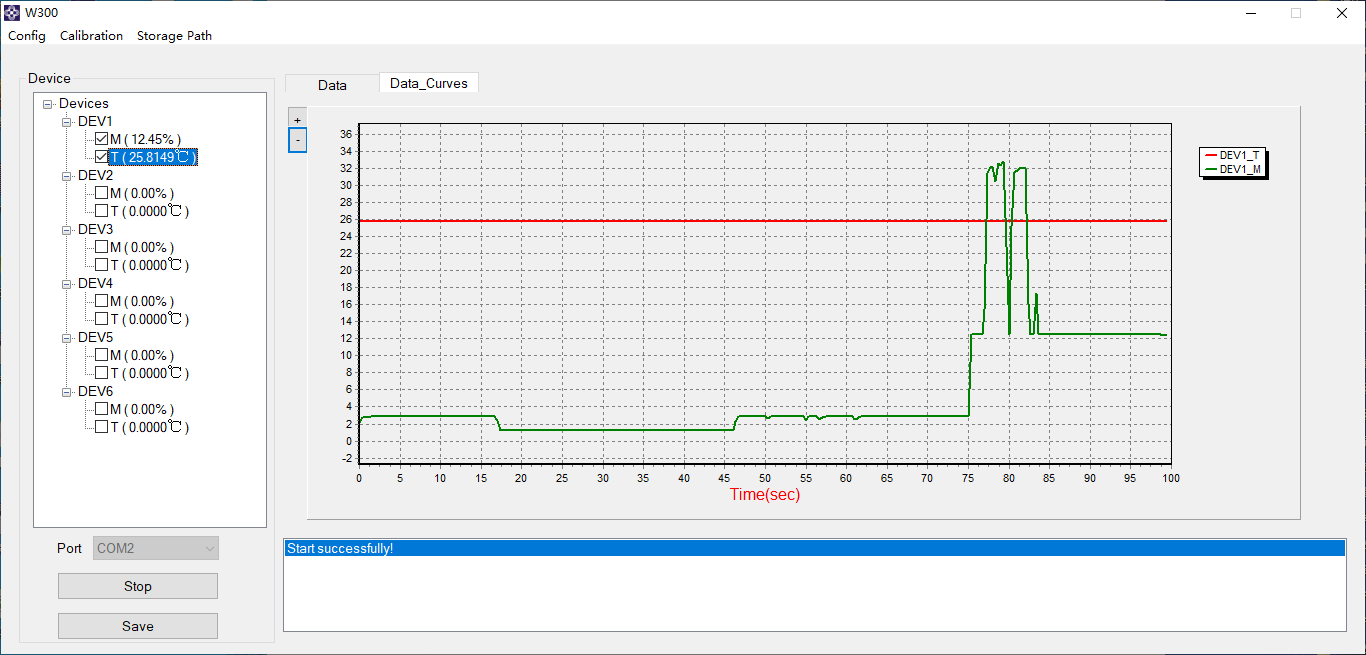

Intelligent PC software

The software features rich functionalities: it can calibrate and display multiple moisture meters simultaneously, automatically record and display curve charts; it provides real-time display of medium temperature, current moisture value, and average value; it allows remote calibration settings for instruments; it can export moisture measurement data, set alarms, print curves, and other functions.

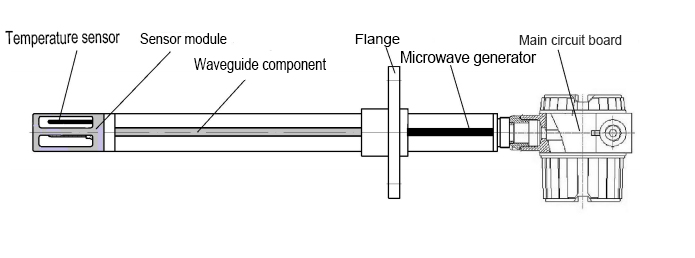

W300 online microwave liquid moisture meter structure diagram

W300 is made entirely of stainless steel, with customizable pressure resistance up to 4 MPa and temperature tolerance reaching 120°C. It is robust and durable, making it an ideal industrial analysis instrument.

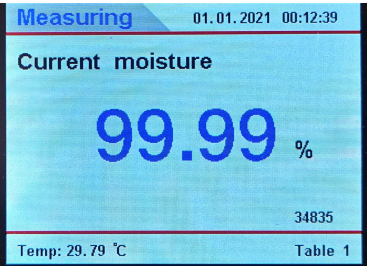

Moisture meter display interface

It can display date, time, moisture value, raw AD value, temperature, calibration table number, etc.

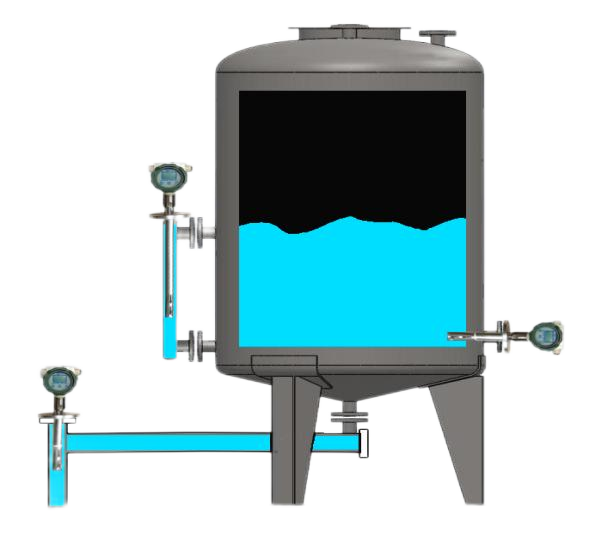

The conventional installation method

1. Pipeline installation 2. Manometer installation 3. Direct insertion installation of storage tank

Chemical plant coal tar moisture pipeline inspection

Crude oil water content measurement at a refinery

Measurement of water content in methanol solution at a chemical plant

Specifications

Parameter | Description |

Range | Model W300: 0-30% |

Typical Accuracy

| 0.04% (range <1%) |

Installation | 2-inch NPT thread or standard flange |

Insertion Depth | Standard 245mm (custom lengths available) |

Weight | Approx. 5kg (standard length with threaded installation) |

Max. Probe Temp | Standard: <80°C |

Temp. Compensation | Yes (required for large temperature variations) |

Probe Material | 304 stainless steel (316L stainless steel or titanium optional) |

Explosion-proof | Ex d IICT6 (optional) |

Output | RS485 and 4-20mA |

Power Supply | 9V-36VDC wide voltage (24VDC recommended) |

Pressure Rating | Standard: <1MPa |

Microwave Frequency | 1GHz,6.8GHz |

Sampling Rate | 1000 times/second |

Protection Rating | IP68 |

Calibration Cycle | Recommended: 12 months |

Display | Date/time, moisture value, AD value, calibration table No. |

Temp. Sensor | Imported digital temperature sensor |

Seal Material | Perfluoro rubber (corrosion/aging resistant) |

Model Selection Table

W300 | -A | -B | -C | -D | -E | -F | -G | -H |

Default: Range (0-30%) H: Range (0-100%) | ||||||||

-B Temperature Default: Standard temperature (<80°C) HI: High temperature (<120°C) | ||||||||

-C Connection method Default: Thread F: Flange | ||||||||

-D Probe material Default: 304 stainless steel | ||||||||

-E Explosion-proof Default: Non-explosion-proof EX: Explosion-proof | ||||||||

-F Pressure resistance Default: Standard pressure (<1MPa) HP: High pressure (<4MPa) | ||||||||

-G Insertion depth Default:245mm | ||||||||

-H Temperature compensation Default: With compensation (required for large temperature variations) | ||||||||

S300 | -A | -B | -C | -D | -E | -F | -G | |

Example:W300H-EX